nCode DesignLife是一款疲劳寿命预测有限元计算分析软件,可对产品进行耐久性设计.分析.,.试验以及管理硬件和软件工具,避免模拟分析您的产品是否超过过度实际负载。30多年来,nCode的产品已经建立了领先的疲劳技术,开拓了世界上第一个商用的,现成的有限元分析为基础的疲劳工具,在90年代初。 从那时起,nCode的产品继续投资于尖端技术,为大型模型尺寸和逼真的负载调度解决方案的开发。 独特的功能,包括预测疲劳分析的频域模拟振动台试验的能力。

在世界各地的主要OEM厂商和他们的供应商使用,DesignLife是行业被证明是最直观,功能强大且灵活的解决方案CAE疲劳和耐久性 。

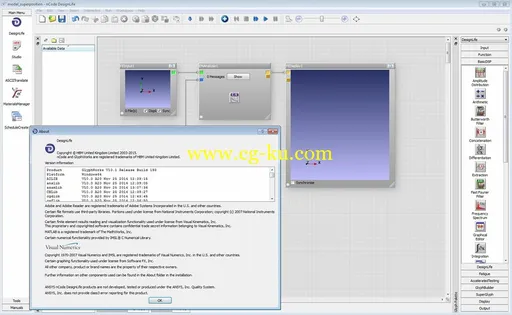

ANSYS 16.0 nCode DesignLife build 193 (Win/Linux) | 1.5GB

nCode DesignLife provides fatigue life prediction from finite element results to answer the question "how long will it last?" or "will it pass the test?" before you even have a prototype. Go beyond simplified stress analysis and avoid under or over-designing your products by simulating actual loading conditions.

For over 30 years, nCode products have established a reputation for the development of leading fatigue technology pioneering the world’s first commercial off-the-shelf FEA-based fatigue tool, P/Fatigue*, in the early 1990’s. Since then, nCode products have continued to invest in the development of cutting edge technology to provide solutions for large model sizes and realistic loading schedules. Unique capabilities include the ability to simulate shaker tests by performing fatigue analysis in the frequency domain.

In use by major OEMs and their suppliers around the world, DesignLife is industry proven to be the most intuitive, powerful and flexible solution for CAE fatigue and durability.

Key Features

Intuitive and easy to use software for performing fatigue analysis from finite element models

Direct support for leading FEA results data including ANSYS, Nastran, Abaqus, RADIOSS, …

Efficiently analyze large finite element models and complete usage schedules

Wide range of fatigue analysis capabilities including stress-life, strain-life, multi-axial, weld analysis, virtual shaker table, and more

Highly configurable for the expert user

Single environment for both Test and CAE data

Enables standardization of analysis processes and reporting

Benefits

Reduce reliance on physical test and avoid costly design and tooling changes

Perform smarter and quicker physical tests by simulating first

Reduce warranty claims by reducing failures

Reduce cost and weight by assessing more design options

Improve consistency and quality with standardized analysis processes

Correlate directly with physical test data

Analyze wind turbine component designs in conformity with GL Renewables Certification's Guideline for the Certification of Wind Turbines (2010)

OS : Windows / Linux 64bit

Language : English Tabletka : Present (Team-SolidSQUAD)

System requirements : 1GB + RAM