Delcam PartMaker是世界领先的专业多轴走心式瑞士型机床和多轴、多任务车铣复合机床CAM 系统,包括走心式瑞士型纵切机床编程专用模块 PartMaker SwissCAM 和多轴、多任务车铣复合机床编程专用模块 PartMaker Turn/MILL 等。广泛支持 Citizen、Star、Tornos、Tsugami等众多品牌的瑞士型纵切机床和近15 年来几乎所有类型的车铣复合加工中心。

Delcam PartMaker产品特点

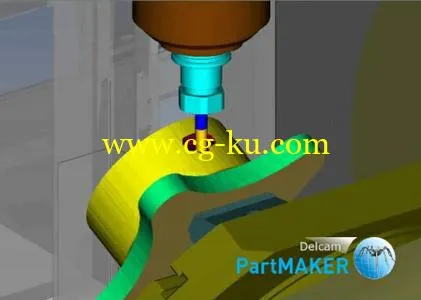

Delcam PartMaker是一款易学易用、编程效率极高的CAM软件,独有的“divide & conquer”(分割而攻克)专利技术,极大地简化了多轴走心式瑞士型机床和多轴、多任务车铣复合机床的加工编程,使制造企业能更轻松地进行零件加工编程并校验NC程序,缩短机床加工设置准备时间,减少编程错误,提高加工效率,降低生产成本。拥有专利技术的直观多转塔、多主轴同步技术,使您能自动仿真同步加工操作。独特的 3D 仿真技术,可确保编制的加工程序无任何错误和碰撞。编程范围涵盖了数控铣、数控车、线切割、车铣复合和瑞士型车削中心。

功能强大——不仅可以满足您现在的需求,也为以后的业务拓展留下了空间

独有的“Divide & Conquer”(分割而攻克)专利技术

复杂零件的高精度编程

自动进行工序同步处理

三维仿真干涉检查

支持全部主流机床

非常强大的走心式纵切和多轴、多任务复合机床的编程能力,轻松胜任

各种结构类型的走心式瑞士型纵切机床

各种结构类型车铣复合机床

多轴、多刀塔的复杂结构机床

易学易用——非常贴近编程人员的习惯

简便、直观的多轴加工编程

基于知识的机床进给和主轴转速设置

自动进行多工序同步优化

快速、容易地生成并校验CNC程序

同样的直观风格可用于所有类型的CNC机床编程

完整的CAD功能

PartMaker集成了强大的CAD绘图功能,可轻松创建几何特征

可进一步输出DXF文件

丰富的输入输出数据接口,可直接读取2D或3D数据

软件兼容性:支持众多CAD软件系统如AutoCAD,Inventor,SolidWorks,Pro/E和UG等等

更多的数据格式:支持DXF、CADL,及STL和Parasolid的实体文件输入等

智能化:实体模型载入之后,自动检测所有需要加工的边界和曲面

双向交流:数据交流不再是障碍

无与伦比的后置处理库和再开发能力

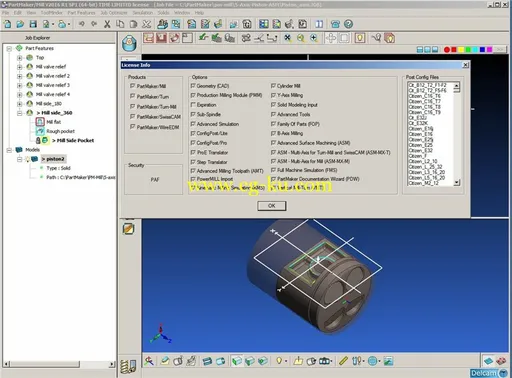

后置极为丰富,约200多种

支持所有主流品牌的瑞士型纵切机床

支持近15年来几乎所有类型的车铣复合加工中心

提供强大的后置客户自定义功能

每个后置都由以下文件组成

后置文件

机床仿真模型文件

后置说明文件

机床配置文件

Delcam PartMaker分部位于美国费城,PartMaker Inc成立于1991年,于2006年7月由Delcam并购。经过多年不懈努力,Delcam 的PartMaker Inc现已成为全球专业多轴走心式瑞士型机床和多轴、多任务车铣复合机床CAM 系统的领先软件公司,产品涵盖了数控铣、数控车、线切割、车铣复合和走心式瑞士型车削中心的CNC编程,产品被广泛用于航空、汽车、医疗、电子、五金和特殊加工行业,用户分布广泛,从规模极小的个体加工车间到众多的《财富》500 强企业都是Delcam PartMaker用户。

支持的机床:

Delcam PartMaker 支持大多数车铣复合中心

Hardinge

Okuma

Miyano

Haas

Daewoo

Hitachi Seiki

Romi

Emco Maier

Yam Seiki

Hyndai

Mori Seiki

Mazak

Nakamura-Tome

Index

DMG

OmniTurn

Wasino

Eurotech

Hwacheon

Kia

Delcam PartMaker 2016 R1 SP1 | 506.0 mb

Delcam has updated the latest version of its PartMaker software for programming CNC mills, lathes, wire EDMs, turn-mill centres and Swiss-type lathes. PartMaker 2016 represents a total game-changer in the field of CAM software for production machining, offering an unprecedented level of power and ease of use.

Major highlights of PartMaker 2016 include powerful 2½ axis milling strategies, support for the import of multiple solid models into a single PartMaker CAM project file, specialist support for broaching, and faster 2D CAD drafting and toolpath selection.

In addition to these technologies, PartMaker Version 2016 includes over fifty additional new features and enhancements.

Headlining PartMaker 2016 is a completely revamped approach to 2½ axis milling operations across the entire product range including PartMaker Mill, Turn-Mill and SwissCAM. PartMaker 2016 offers a host of new 2½ axis milling options based on parent company Delcam’s proprietary milling technology, technology developed and supported by the industry’s largest CAM-focused development team. This new milling functionality is specifically targeted at the needs of production machining applications, allowing users not only to program faster but also machine parts faster than ever before.

The new milling toolpath technology included in PartMaker 2016 offers an unprecedented combination of power and ease of use. It allows users to create highly efficient and sophisticated toolpath strategies without even requiring a solid model.

PartMaker 2016 also offers users the ability to import multiple solid models into a single PartMaker CAM project file (*.JOB file). Additionally, this new functionality lets users quickly extract multiple parts from an imported solid assembly and so allows more flexible programming of complex parts as well as improved ability to manipulate milling workholding in PartMaker’s CAM environment.

PartMaker 2016 also includes the CAM software industry’s first, dedicated functionality for broaching. Broaching is a deformative manufacturing technique for creating features with sharp corners. While broaching has its roots in old world screw machine technology, it has become a popular machining technique today, particularly in the medical device field in bone screw applications with hex shapes, Torx or Hex lobular and square and spline drives.

PartMaker 2016 automates the programming of both index and rotary (also known as wobble) broaching operations in an intuitive and visual manner. The software allows broaching operations to be simulated using powerful, 3D simulation.

About Delcam plc

Delcam is a world-leading developer and supplier of advanced CADCAM software, with more than 35,000 customers in over 80 countries. These clients vary from global names like Nike, Boeing and Mattel to small start-ups and individual craftsmen. Founded 30 years ago, we are the largest developer of product development software in the UK, with subsidiaries in Europe, America and Asia. Our global success has been recognised with many awards, including three Queen’s Awards for Enterprise in the last six years.

Name: Delcam PartMaker

Version: (64bit) 2016 R1 SP2 (CB 1055217)

Interface: multilanguage

OS: Windows 7even / 8 / 10

Size: 506.0 mb