Overland Conveyor Bulk Flow Analyst 15.0 | 200.2 mb

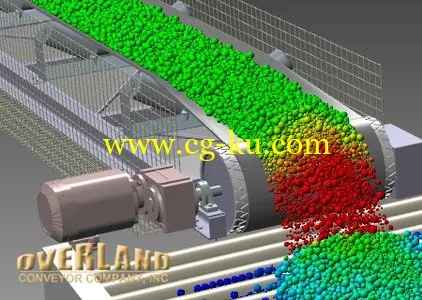

Overland Conveyor Company Inc. has released the 15.0 version of Bulk Flow Analyst is used to simulate conveyor transfer flow: Prevent Chute Plugging, Minimize Belt Wear, Minimize Chute Surface Wear, Mimimize Dust, Minimize Spillage, Minimize Material Degradation.

Applied DEM is committed to providing bulk material handling solutions through use of our software backed by proven discrete element method technology. We provide tools that aid in the design phase of bulk material handling problems. The use of our simulations help identify potential problems before full implementation, saving our users time and money.

Bulk Flow Analyst 15.0 New Features:

Custom Clusters

Applied DEM introduced the ability to define clusters several releases back. Clusters give users the ability to define a particle shape that isn't purely spherical which allows the geometry to drive how the particle moves. In previous versions of the software, users had to define multiple material condition components to define multiple cluster shapes. Each time an injection box was added to a simulation, users would have to add each of the material conditions and apply the approriate breakdown of mass contributed by each material condition. Starting in version 15.0, users can define multiple cluster shapes in a material condition, much in the same way Custom size-distribution is used. The user specifies a number of cluster shapes to use, then defines the shape and mass fraction this shape contributes to the material.

Particle Blocks Allow More Materials

Prior to BFA 15, Particle Block components (Uniform nor Random) could not accept a material condition with a material size range. Particles had to be uniformly sized. For Random materials, this meant that the Min and Max size had to be equal. Custom materials were simply not allowed. Clusters were not allowed at all.

Now users of Random particle blocks are able to use material conditions with a size range. Random materials and Custom materials with size ranges can be generated within a particle block. Random particle blocks can also accept material conditions generating clusters, whether those are custom clusters or not.

Motion Manager Makes a Strong Comeback!

Users of BFA prior to version 14 were able to use a tool called the Motion Manager, which allowed users to define complex movements for components. Components were able to move and rotate, stop, reverse direction, and easily link one component's motion to another moving component (think leg-bone connected to the thigh-bone). This tool simplified the definition of common components like flop gates and dump bodies that remain stationary, then rotate, then remain stationary again. However, it also allowed for the definition of more complex motions, such as bucket wheels rotating on two axes. Due to the change of numerical engines, BFA version 14 did not include the Motion Manager. But it's back!

Enter the value of your component's surface ID on the center right, then use the translation, local rotation, and global rotation tabs to specify distances and angles traveled in a given time range. Enter negative distances to move backward, overlap motions, link this component's motion to another moving component, the possibilites are nearly limitless. Click "Save Files" and run your simulation as usual. You can simulate extremely complex motions, all the while BFA will be determining how these motions affect the flow of your materials.

About Overland Conveyor Company Inc.

Professional engineers specializing in the belt conveyor design, engineering and technical support. Develops and markets a full range of belt conveyor software tools. Develops and markets Discrete Element Modeling software tools for the simulation of bulk material flow.

Name: Overland Conveyor Bulk Flow Analyst

Version: 15.0

Interface: english

OS: Windows XP / Vista / 7even / 8 / 8.1

Size: 200.2 mb