Automation Studio是一个完全整合的软件包,用户能够使用它作设计、资料编制、模拟以及演示各种技术回路,包括液压、气动、电路控制、可编程逻辑控制器(PLC),顺序功能图(SFC/Grafcet)以及其它多项技术。

Automation Studio可以在一个普通的环境里下(窗口系统下), 独特的整合了系统设计特征的易操作性、高级工程能力、动态现实模拟、完整的演示特征和灵活的资料编制功能。 它在优化系统应用、部署和维护方面为生产商、OEM商和终端客户开辟了一个新的领域。在整个设备生命周期的每个环节提高生产率的同时,Automation Studio?为设计工程、试制样品、测试、排除故障、维护/诊断、培训和技术发布提供无缝整合。

Automation Studio现在标准配置几个模块和函数库。在模拟时所有模块和函数库相互交互,因此,可以允许你创建就像真实状况下运行的完整系统。每一个函数库包含几百个符合ISO,IEC,JIC和NEMA标准的符号。将合适的组件拖放到工作空间以后,你可以迅速重建和模拟系统。

你也可以自定义你的函数库以及根据你每次特定练习的需要对其进行布置,节约查找组件的时间。

Automation Studio有以下的模块和函数库

1. Hydraulics (液压设计)

2. Proportional and Servo Hydraulics (比例和伺服液压)

3. Pneumatics (气动设计)

4. Fluid Power Component Sizing (流体传动组件编辑)

5. Spool and Pump Designer (线管和水泵设计)

6. Bill of Material & Report (材料单和报告单)

7. Electronic Catalog (电子目录)

8. PLC Ladder Logic & Digital Electronics (可编程逻辑控制器梯形逻辑及数字电子)

9. HMI and Control Panel Module (人机界面和控制面板模块)

10. Digital Electronics Library (数字电子库)

11. Sequential Function Chart(SFC)/Grafcet (顺序功能图)

12. OPC Client & I/O Interface Kit (OPC客户端和输入/输出接口工具包)

13. Electrical Controls (电气控制)

14. Electrical (电气函数库)

Automation Studio 的优点如下:

1. Automation Studio助你的机构提高质量、加速工作流以及提高生产率,优化你的整体工作流。

2. Automation Studio是一个完全整合的软件包,使得用户能够设计、资料编制、模拟以及演示各种技术回路。

3. Automation Studio提供全色动态和现实模拟,节约样品制造和维护成本。

4. Automation Studio有几千个模数库符号包括ISO, DIN, IEC, NEMA 和 JIC的图形标准,而且可以自定义你自己的符号、组件、模板和函数库。

5. Automation Studio可以与其它CAD和PDM系统兼容便于流畅的整合。

6. Automation Studio通过提供一个仅用于模拟的运行时间版本 -Automation Studio? Runtime(ASR),机构组织就有了一个节约成本的方法执行现场培训和机器诊断。

7. Automation Studio真正的模拟和演示功能帮助教创建动态、生动和灵活的培训材料员示范和证明由简到繁的原理

Automation Studio P6 SR9 | 1.1 Gb

Famic Technologies Inc. presents Automation Studio engineering software, version 6.0 SR9, its trade-oriented system design, simulation, documentation, training and maintenance software solution for fluid power, electrical and automation.

P6 is the 4th complete Automation Studio new design.

With this release, companies can safely perform collaborative work on a project or share key information, be it with customers, suppliers, or colleagues. This new version helps OEMs, vendors and machine builders create companywide standards and enhanced project documentation with its new multi-user, multi-language and remote access features.

P6 allows users to define defect scenarios in order to trigger failures during system simulation. A set of virtual dynamic instruments help diagnose and repair these failures. This provides a safe and efficient environment to train maintenance and service personnel and sharpen their skills relating to specific equipment or systems. The result: reduced equipment downtime and increased productivity.

The user interface detects the discipline (i.e. fluid power, electrical, automation) and automatically adapts by displaying applicable commands and functions. The screen s workspace is optimized by using current concepts. The new API and Scripting module gives users access to an entirely new level of integration with other corporate applications. Moreover, the multi-user support capability allows several geographically dispersed teams to simultaneously design and simulate the various systems of a machine.

Ready-to-use components are available in several catalogues, which facilitate hydraulic system design. The production of these catalogues is made possible thanks to the on-going collaboration with a number of manufacturers: Eaton, Hydraforce, Linde, Bosch Rexroth, Sauer Danfoss, Comatrol, Delta Power, Sun Hydraulics, and others. Each component has been rigorously bench-tested within Automation Studio to ensure that its simulation meets the manufacturers typical application and performance specifications.

Service Release 9 addresses issues that were found through a combination of customer and partner feedback, as well as internal testing. This service release offers Automation Studio P6 users the following improvements:

- More advanced simulation of transient phenomena with step times of 100 microseconds and above

- Dynamic valve modeling including venting pilot valves

- New settings and interfaces to facilitate the modeling of a number of components

- Component symbols can be configured with the options in the manufacturers’ catalogues

- And more…

About Famic Technologies

Famic Technologies offers a complete range of high-end products and services in the fields of software engineering, industrial automation, and software applications for administrative needs. Innovation, quality and performance are the cornerstones of this company. For more than 25 years, Famic Technologies has remained one step ahead, particularly in the development of CAD solutions and simulation of automation technologies.

In 1995, Famic Technologies was among the first Canadian companies to have its continuous efforts in research and quality control rewarded with ISO 9001 certification..

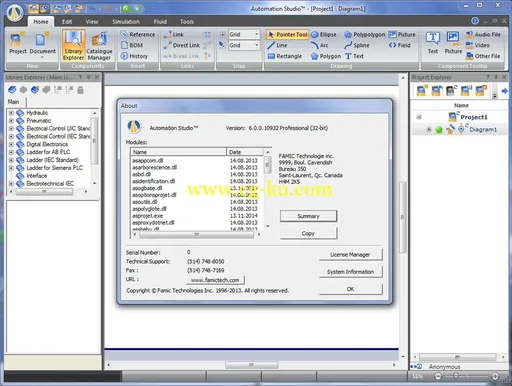

Name: Automation Studio

Version: (32bit) 6.0.0.10932

Interface: english, french, german, spanish

OS: Windows Vista / Seven / 8

Size: 1.1 Gb