LVMFlowCV -铸造技术开发的专业解决方案。 现代铸造技术生产的铸件质量高,相当复杂的几何形状,几乎不需要任何额外加工。 然而,生产费用仍然高。 高端技术的应用,特别是铸造冻结期间发生的物理化学过程的计算机模拟系统允许从一个侧面合金的使用范围更从另一个侧面转向更多和更复杂的几何形状的铸件技术结帐减少开支取代真实实验与计算机之一。 现代系统的计算机模拟的基础上的热扩散,流体动力学和变形现象的物理理论能够充分反映发生在模具填充液态金属,在多组分合金中结晶,退火等的物理化学过程的模式。

LVMFlowCV 4.6 | 446.6 mb

LVMFlowCV – it is a competent solution for foundry technology developers. The modern foundry technologies by this time allow to produce castings of high quality, quite complex geometry, practically aren’t requiring any additional machining. However production expenses are still left high. Application of high-end technologies particularly systems of computer simulation of physicochemical processes taking place during casting freezing allows from one side to turn to castings of more and more complex geometry using even more range of alloys, from the other side to reduce expenses on technology checkout, by replacing the real experiment with computer one. The modern systems of computer simulation based on physical theories of heat, diffusion, hydrodynamic and deformation phenomena are capable to adequately reflect the pattern of physicochemical processes occurring at the mold filling with liquid metal, at crystallization of multi-component alloy, annealing and so on.

More info: this

About MKM Ltd.

MKM Ltd. Development and adoption of the most up-to-date foundry technologies on the base of computer simulation system of casting processes LVMFlowCV.

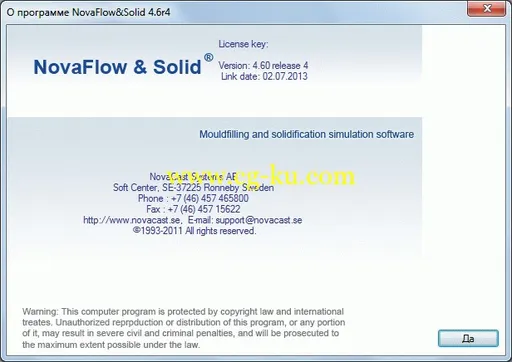

Name: LVMFlowCV

Version: 4.6 Build 4

Interface: multilanguage

OS: Windows XP / Vista / Seven / 8

Size: 446.6 mb