ESPRIT是由美国DP Technology公司推出的一款针对高端数控机床应用的CAM软件

无限制机床编程

高性能的ESPRIT系统为任何一种CNC机床提供了强大的编程能力。ESPRIT的全功能包括2-5轴铣削,2-22轴车削,2-5轴线切割,多任务车铣复合加工,以及带B轴的机床编程,功能强大而灵活的ESPRIT系统使您的加工效率更高。基于其丰富的加工类型,以及全面的刀具控制和支持全车间生产的能力,ESPRIT系统得到所有CNC程序员的一致好评。

加工任何几何形状

ESPRIT的CAD到CAM之间的无缝接口能够导入任意来源的完整无缺的原始零件模型,无需程序员编辑或重建几何模型。ESPRIT能够直接加工出任何一个由实体,面,线框或STL构成的几何复合体,这为您提供全面而灵活的加工策略。从100%完整和精确的零件几何形状开始,ESPRIT能够帮助您消除复杂零件编程中的几乎所有的难点,大幅度降低了编程的时间。

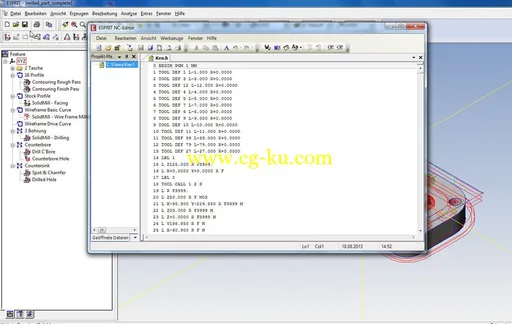

通用后置处理器

ESPRIT通用的后置处理器能够方便地生成高效的,充分发掘机床潜力的G代码。使用完整的预定义的后置处理器库,用户可获取值得信赖的加工操作。针对于各类世界知名品牌的高级机床,ESPRIT提供了多种相应的预设后置处理器。ESPRIT的开放式结构使您能够方便地调整任意的后置处理程序来适应您的编程习惯和车间要求。ESPRIT完美的G代码意味着您可将有更多的时间用于零件加工,以尽可能低的成本获得机床能力的最大利用和最优的零件质量。

动态仿真及检测

ESPRIT快速,准确,可靠的动态实体仿真及检测功能避免了NC机床上昂贵的试运行操作。在您对“设计产品”与“加工产品”作精确比较时,可以完全信赖这一加工过程。ESPRIT高效的实时仿真和全面的碰撞检测功能,帮助您即使是制造最复杂的零件也能首先确保加工的高度准确性。ESPRIT可以在真实模拟的加工环境下对整个加工过程做详尽的仿真以及检测:包括机床、夹具、压板、毛坯,以及工件。因此,您可以完全信赖ESPRIT动态实体仿真及检测功能,从而最小化停工时间,提升生产效率,降低切削加工成本。

DP Technology ESPRIT 2013.R3 | 1.32 Gb

ESPRIT 2013, the latest version of the innovative computer-aided-manufacturing (CAM) software developed by DP Technology Corp., designed to program multi-spindle, multi-turret mill-turn and Swiss-turn machine tools.

This latest version focuses on providing new and enhanced machining technology that ensures more efficient toolpaths and new strategies for greater overall productivity, the company says.

New to ESPRIT 2013, the patent-pending ProfitMilling strategy for 2-, 3- and 5-axis roughing cycles allows customers to remove more material in a shorter period of time. The ProfitMilling strategy optimizes engagement angle, chip load, material removal rate (MRR), lateral cutter force and machine acceleration to achieve optimal results. It utilizes trochoidal tool motion and a traditional offset of the toolpath, allowing usage of the full tool flute length.

Other upgrades include a new plunge setting added to the plunge turning (zigzag) cycle. Using a pre-plunge along walls reduces the tool load against walls and cuts wide grooves faster. A lateral feed-rate setting provides customers with more control and an option to perform extra-plunge along a profile to deliver fewer scallops for the finish pass. Also new are two new strategies for the "Diagonal Zigzag" groove type: "Thin-to-Thick Chip" for a progressive engagement of the tool, and "Thick-to-Thin Chip" that is suited to ceramic inserts. It generates rapid metal removal without vibration, as well as improved finish and prolonged tool life.

A new 5-Axis Roughing Cycle has been designed to quickly and easily rough a 5-axis part using the same familiar technology used to rough a 3-axis part, including the new ProfitMilling pattern. The 5-Axis roughing cycle automatically adjusts the orientation of any tool shape (end mill, ball mill, bull-nose mill) to keep the tool perpendicular to the underlying surface, thereby eliminating undercuts.

Also new to ESPRIT 2013 is a 5-Axis Port Machining Cycle dedicated to machining cylindrical apertures, and devised to cut as deeply as possible into a port while containing tool swings. This cycle is aided by an automatic recalculation of tool points along a spine curve.

The Impeller Machining Cycle now includes built-in re-machining, which allows for the complete machining of an impeller without concern for tool dimensions. The impeller cycle allows customers to machine as far as possible using the current tool before automatically stopping at the first unreachable level.

New collision-detection strategies have been added to all 3-axis and 5-axis milling operations, which detect collisions while toolpath is being calculated instead of during the simulation process. ESPRIT can be instructed to recommend the minimal tool length to avoid collision, or to automatically trim away the colliding toolpath and reconnect with appropriate links.

The new "Mid Surface" function can be used for blade machining, where it allows for the calculation of toolpath from a single source instead of multiple faces on the model, and controls the orientation of the tool axis throughout the cut, rather than on individual surfaces of the blade.

Name: DP Technology Esprit

Version: 2013.R3

Interface: multilanguage

OS: Windows XP / Vista / Seven

Size: 1.3 Gb

Team MAGNITUDE