Altair宣布引入一款流程化且高精度的垂直应用程序HyperWorks Virtual Wind Tunnel™ ,专用于改善汽车行业中的风洞仿真。Altair公司在Garden Grove(美国加利福尼亚州)举办的年度“Altair北美地区技术大会”Americas Altair Technology Conference上宣布了这一消息。

HyperWorks Virtual Wind Tunnel 充分利用高级网格划分及高保真计算流体动力学仿真等多种 Altair 最先进技术,并采用直观、高度自动化和流程化的工作流程与用户界面,将车辆外流场性能的精度和速度预测推向新高。

外流场仿真在现代汽车设计中扮演着举足轻重的角色。车辆的燃料消耗量、稳定性、发动机冷却、驾驶室内部噪声以及风挡刮水器的性能均与空气动力作用息息相关。借助采用计算流体动力学 (CFD) 的风洞仿真,工程师可以对这些空气动力载荷进行研究,并能减少车辆开发过程中所需的物理风洞测试。

“HyperWorks Virtual Wind Tunnel 基准测试表明,Altair 的技术与实际风洞结果非常吻合,”Altair CFD 技术副总裁 Farzin Shakib 博士表示,“我们可以预见,HyperWorks Virtual Wind Tunnel 的易用性、灵活性、精度和速度定会使其风靡整个汽车行业,并在建筑设计与构造以及风轮机开发等其他需要进行外流场仿真的领域中掀起使用热潮。”

该解决方案的核心便是行业领先的Altair CFD 求解器AcuSolve®,其计算速度快、扩展性强、功能强大且精度高的特点使之脱颖而出。借助 AcuSolve 先进的湍流建模技术,HyperWorks Virtual Wind Tunnel 能够利用稳态及瞬态仿真对流场和气流分离进行预测,从而更快获取更加精确的结果。AcuSolve 所提供的行业顶尖流体结构耦合解决方案将结构的灵活性考虑在内,可实现更为真实、全面的汽车虚拟风洞仿真。

“AcuSolve 是我们进行外部空气动力学仿真的首选解决方案。更具体地说,使用 AcuSolve 进行外流场仿真,可以更容易获得更加精确的阻力测量结果。”工程仿真及咨询公司 Lx Sim总裁 Geneviève Dutil 说道。

HyperWorks Virtual Wind Tunnel 的另一项优势在于其高级网格划分功能。HyperWorks Virtual Wind Tunnel 以强大的网格划分技术为依托,提供了具有边界层的快速、全自动非结构化网格划分器。汽车外流场分析的体网格划分(包括车身底板、发动机舱以及边界层)在两个小时之内即可完成。作为 HyperWorks Virtual Wind Tunnel 的核心,CFD 求解器不仅对单元质量具有较强的包容性,还能够管理对于复杂几何无法避免的严重失真单元。其他解决方案的网格优化步骤通常需要时间的集中投入,而求解器的灵活性便打破了这一常规,从而大大减少了网格划分所需时间。

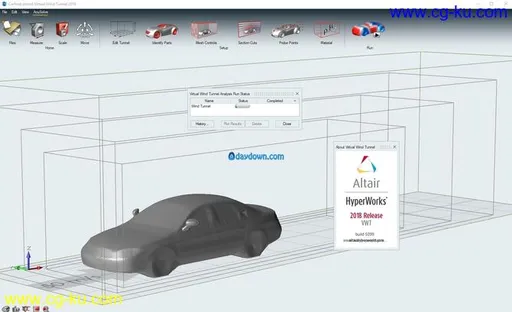

HyperWorks Virtual Wind Tunnel 不仅具有友好直观的用户界面,还提供了高度自动化的设置过程。仿真可从 HyperWorks Virtual Wind Tunnel 环境中轻松提交至高性能的计算系统中。

关于Altair

Altair的产品和服务通过优化对商业和工程信息的分析、管理和可视化,致力于增强客户的创新力和决策力。Altair目前为私人所有,在全球拥有2000多位员工,分支机构遍及美洲、欧洲及亚太地区。凭借其在产品设计、先进工程软件和网格计算技术上28年的经验,Altair不断为各个行业的客户创造竞争优势。

Altair Virtual Wind Tunnel 2019.0 | 1.5 Gb

Altair introduced Virtual Wind Tunnel 2019.0, a streamlined and high quality vertical application designed to improve wind tunnel simulation for the automotive industry.

About Altair Virtual Wind Tunnel.

Leveraging several of Altair’s state-of-the-art technologies from advanced meshing to high-fidelity computational fluid dynamics simulation, and designed with an intuitive, highly automated and streamlined workflow and user interface, HyperWorks Virtual Wind Tunnel brings new levels of accuracy and speed in predicting a vehicle’s external aerodynamic performance.

External aerodynamic simulation plays an important role in modern automotive design. The vehicle’s fuel consumption, stability, engine cooling, interior cabin noise and windshield-wiper performance all are influenced by aerodynamic forces. Wind tunnel simulations employing computational fluid dynamics (CFD) allow engineers to study these aerodynamic loads and can reduce the number of physical wind tunnel test experiments required during a vehicle’s development process.

Central to the solution is AcuSolve, Altair’s industry-leading CFD solver that is highly differentiated by its speed, scalability, robustness and accuracy. AcuSolve’s advanced turbulence modeling technology enables HyperWorks Virtual Wind Tunnel to predict the flow field and flow separation using steady-state and transient simulation for faster and more accurate results. The best-in-class fluid-structure interaction solution from AcuSolve allows more realistic and comprehensive automotive virtual wind tunnel simulation by considering the flexibility of structures.

Another advantage of HyperWorks Virtual Wind Tunnel is its advanced meshing capabilities. Built on a powerful meshing technology, HyperWorks Virtual Wind Tunnel comes with a fast, fully-automated unstructured mesher with boundary layers. Volume meshing for an external automotive aerodynamics analysis—including the underbody, underhood compartment and boundary layers—can be completed in less than two hours. The CFD solver at the core of HyperWorks Virtual Wind Tunnel is highly tolerant of element qualities, with the ability to manage badly distorted elements unavoidable for complex geometries. The solver’s flexibility eliminates the time-intensive mesh optimization step often required with other solutions, dramatically reducing meshing time.

HyperWorks Virtual Wind Tunnel provides a friendly, intuitive user environment and a highly automated setup process. The simulation can be submitted easily to high-performance computing systems from within the HyperWorks Virtual Wind Tunnel environment.

In this video overview of Altair’s Virtual Wind Tunnel (VWT) used for external aerodynamic analysis. Topics will include model preparation, design changes using morphing, solver technology (Navier-Stokes) and shape optimization.

About Altair.

Altair is a leading provider of enterprise-class engineering software enabling innovation, reduced development times, and lower costs through the entire product lifecycle from concept design to in-service operation. Our simulation-driven approach to innovation is powered by our integrated suite of software which optimizes design performance across multiple disciplines encompassing structures, motion, fluids, thermal management, electromagnetics, system modeling and embedded systems, while also providing data analytics and true-to-life visualization and rendering.

Product:

Altair Virtual Wind Tunnel

Version:

2019.0 Build 5099

Supported Architectures:

x64

Language:

english

System Requirements:

PC *

Supported Operating Systems:

Windows 7even (64bit) or Windows 10 (64bit)

Software Prerequisites:

Altair Acusolve 2018 or Altair CFDSolvers 2019

Size:

1.5 Gb

* Review System Requirements:

RAM: 4 GB (higher recommended) Graphics Hardware: OpenGL 3D graphics accelerator compatible with OpenGL 3.2 or higher, True color (24-bit) support, 2 GB or higher dedicated RAM, Only AMD and NVIDIA GPUs supported (Intel chipsets are not supported)

发布日期: 2019-06-18