File size: 82 MB

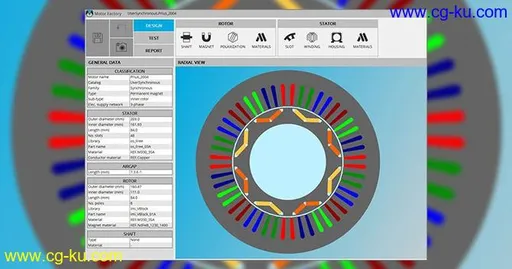

Increasing efficiency by changing design paradigms for electric equipment. Global system performance prediction – from the design of the device to its final operational efficiency – using the most efficient design tools and methods, is key for organizations to innovate. FluxMotor is a flexible standalone software tool focusing on the pre-design of electric rotating machines. It enables the user to design and create motors from standard or customized parts, as well as to intuitively add windings and materials to run a selection of tests and compare machine behavior.

Addressing a broad range of users, FluxMotor is easy to use with an efficient working environment allowing for the creation and performance evaluation of an electric motor within a few minutes.

Benefits:

High productivity gain

Automatically driven workflow offering an efficient user-oriented environment to different level of users

Facilitated project management, allow a quick access to past studies and to manage the full range of products

Creating a model of an electric motor and evaluating its technical-economic potential within a few minutes

No compromise on accuracy

Based on optimization technology, FluxMotor helps reduce computing time to the minimum, while maintaining accurate results

Computing methods wisely using the high power of finite element modeling

Settings adapted to the task levels of accuracy vs. rapidity

Connection for advanced studies

Easy project export to Flux to perform advanced studies like eccentricity, vibro-acoustic, etc.

At any time, the full parameterized Flux project, with all the physical properties embedded, is ready to be solved in Flux environment

Capabilities:

Effective machines parts management

Libraries are provided with standard parts

A wide variety of slots or magnets are available

All the topologies are parameterized

Offered standard parts, slots or magnets, can be edited and customized for unlimited configuration

Productive interfaces to shape the machine

Step by step, from the shaft, rotor magnet to the slot, winding and housing of the stator, a dedicated interface guides users to finalize machine design

4 different winding modes (from automatic to expert) help users to find the right winding architecture

Comprehensive and scalable material database

Testing and evaluating electric motors

The FluxMotor dedicated test environment enables users to assess motor performance

Example of tests ready to be performed

Maps vs (Id, Iq): Flux, inductance, torque, iron losses, etc.

Open circuit tests with cogging torque and back-emf

Torque-speed curves & efficiency maps

Relevant input parameters allow users to control the test conditions

A detailed motor datasheet can be edited and exported

Powerful project management

The motor catalogue environment allows easy management of motors projects, helping the user to classify the machine and offering quick access to past studies

The general data and performance of several machines can be compared and help simplify the machine choice

发布日期: 2019-08-28