Mastercam

X9 version 18.0.15514 Update | 678.5 mb

CNC Software, Inc., a developer and provider PC-based software tools for CAD/CAM manufacturing markets, announces update the release of Mastercam X9. This release brings a new suite of programming tools focused on delivering speed, automation, and efficiency for all machining jobs.

Mastercam X9 introduces Dynamic Motion improvements, multiaxis enhancements, and many Design and System features to make your job easier.

Dynamic Motion Technology

Dynamic Motion toolpaths follow a proprietary and sophisticated set of rules that take into consideration a broad data set. To create the most efficient cutting motion possible, Dynamic toolpaths calculate not only the area where metal will be removed; they also take into account the changing condition of the material throughout various stages of machining.

Design Features

Dynamic Xform allows you to switch between gnomon manipulation and geometry manipulation mode at any time without having to reselect geometry. Solid Disassemble is a new Model Prep function that takes an assembly and lays each body out in a single pane. With Mastercam X9, the associativity between solids and toolpaths has been greatly improved. Now when bodies are edited, only the toolpaths directly affected by the change in the solid body are marked dirty.

Multiaxis Improvements

The new Multiaxis Link ensures reposition moves between 2- through 5-axis operations are safe and collision-free. Multiaxis Link is an operation that takes a list of toolpath operations and a safety zone shape as input. Mastercam X9 introduces improved processing logic for advanced multiaxis toolpaths. Select multiaxis toolpaths now process in the Multi-Threading Manager, streamlining your 2- through 5-axis workflow experience.

Also available in Mastercam X9:

-Preview Toolpaths support for select Mill operations to see your results before closing the toolpath parameters dialog.

- Surface High Speed Hybrid now supports dedicated flat processing, making Hybrid even more intelligent and efficient.

- The efficiency of the 3D HST Rest Roughing Linking has been improved. The moves are closer to your model, eliminating costly excessive air motion.

- Mill Tooling introduces two new tool types, as well as changes to two existing tools.

About CNC Software, Inc.

CNC Software, Inc. provides PC-based software tools for CAD/CAM manufacturing markets. It offers design tools, such as Mastercam Design, a streamlined 3D CAD software that is included in various Mastercam CAM packages; and Mastercam Solids, an add-on that lets users create, import, and machine solid models. The company also provides Mastercam Mill, a programming package for 2, 3, 4, and 5-axis milling; Mastercam Lathe, a CNC programming system for simple to complex turning; Mastercam Router, a CAD/CAM system for routers; Mastercam Wire for wire EDM programming; Mastercam Art that allows to design and machine 3D work from flat art, drawings, and photographs; Mastercam Maintenance services; and Mastercam add-ins. In addition, it offers technical support and online corporate training services. The company serves mold making, automotive, aerospace, educational, jewelry, medical, military, music, production shop, prototyping, racing, sporting goods, tools and dies, transportation, woodworking, and consumer industries worldwide. It sells its products through a network of dealers and authorized resellers. The company was founded in 1983 and is based in Tolland, Connecticut.

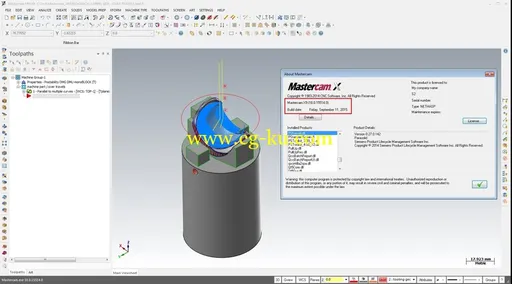

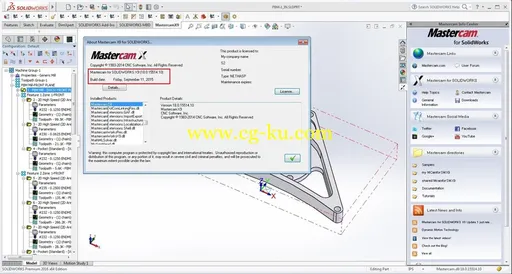

Name:

Mastercam and Mastercam for SolidWorks

Version:

(64bit) X9 Build 18.0.15514.0 and (64bit) X9 Build 18.0.15514.10

Home:

http://www.mastercam.com

Interface:

english

OS:

Windows 7even / 8 / 8.1

System Requirements:

SolidWorks 2010-2015 (for Mastercam X9 for SolidWorks)

Size:

678.5 mb

Bonus: Mastercam SDK X7-X9

发布日期: 2015-10-18