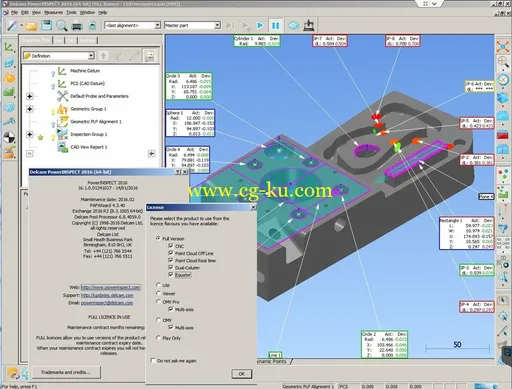

PowerINSPECT是被广泛应用,支持多种测量设备类型,功能强大,易学易用的独立检测软件系统。PowerINSPECT提供强大的CAD数据接口转换软件,与广泛格式的三维数学模型进行联机或脱机检测比较误差分析,生成图文并茂的、符合PTB认证、符合ISO9002标准的、清晰易懂的检测报告。

拥有基于PowerINSPECT的检测软件平台,就能够满足制造企业各种类型的检测设备和软件接口的需求。制造企业不需要再为采购新的检测设备而额外购买新的检测软件,更不需要去学习不同检测设备所配备的专用的、复杂的检测软件,同时也可以极大地提高企业检测人员的工作效率,为制造企业节省大量的资金、时间和人力成本。

PowerINSPECT的家族成员:

● PowerINSPECT手动模块: 臂式检测设备/CMM座标测量机

● PowerINSPECT CNC模块: CNC/DCC CMM座标测量机

● PowerINSPECT在机检测模块: 数控机床在机检测(OMV)

● PowerINSPECT点云模块: 激光、光学等特殊检测设备

● PowerINSPECT阅读模块: 脱机数据分析,输出报告

● PowerINSPECT自适应加工模块: 自适应加工定位

● PowerINSPECT机床精度检测模块: 机床精度检测及测头校准

PowerINSPECT的特点:

· 易学易用

· 支持广泛的检测设备与检测技术类型

· 支持所有主流三维CAD模型输入、输出

· 快速对齐定位

· 完整的几何形体检测能力

· 自动化形位公差检测向导

· 检测过程与结果可靠

· 高品质质量检测报告

· 多年的经验积累

PowerINSPECT易学易用,纯中文的、符合WINDOWS规范的、简洁明快的界面和极富人性化的操作方式,只需要两天,即一天的软件操作培训,一天的现场联机操作培训,就能够轻松掌握所有的技术内容,并能独立完成制造业所需的、从简单的标准体素到复杂的自由型面检测的全部工作,并快捷地输出图文并茂、清晰易懂的、符合PTB认证、符合ISO9002认证标准的检测报告!

Delcam PowerInspect 2016 SP0 | 953.2 mb

Delcam has released the 2016 version of its PowerINSPECT inspection software, the world’s leading hardware-independent 3D inspection solution. The new release includes greatly enhanced options for section measurement, more comprehensive collision avoidance, improved point cloud inspection, the ability to add notes to reports, and improved user control of CNC surface inspection routines.

Section inspection has been improved with easier creation of sections, better visualization and enhanced reporting. The enhanced options for section editing in PowerINSPECT 2016 include a slider that can be used to move the section through the part with real-time updating of the CAD view. A specific value for the section intersection can still be entered if required.

New graphics options help with visualization and reporting. In the CAD view, the default option highlights the section cut and displays a semi-transparent representation of the material in the foreground, providing an accurate 3D visualization of the section in place on the part. During section creation the shading is updated dynamically as the section moves through the model. Alternatively, the near side can be hidden completely, or the complete CAD model can be shown in a solid color as before.

Once the desired section has been chosen, the inspection path can be generated automatically. The points generated can be edited if necessary. The section can also be viewed and reported as a 2D true view of the section profile that is currently selected.

As with other PowerINSPECT measurements, the results of the section inspection can be viewed as spot confetti, deviation lines or vector lines. The results can be displayed either on their own or as part of a larger inspection sequence.

Automatic collision detection was introduced in PowerINSPECT 2015, with probe paths adjusted automatically when a direct move between inspection features would result in a collision. A new collision-free mode extends this capability by automatically creating links between inspection features as necessary. If a potential collision is detected, the software automatically creates and calculates a new linking path that avoids the obstacle. Collision avoidance is recalculated when the order of the inspection sequences is adjusted in the sequence tree.

Intermediate paths can still be created or updated manually. This is required when the CAD model does not include complete information about the physical reality, for example if clamps or fixtures used to hold the part are not included in the CAD data.

PowerINSPECT 2016 has improved reporting with the ability to include additional user-defined information. New ‘Report Note’ items allow the user to insert additional observations, including text and pictures. As with all other items in the report, the notes can be shown, hidden and re-ordered within the report.

The formatting of labels has also been enhanced, particularly for GD&T items. New options have been added to the dialog for session settings to enable further control of the label display. Furthermore, the label sizes can be edited in the session settings and grid lines can be displayed for clearer reporting.

A number of enhancements have been added for inspections based on point clouds. Firstly, point clouds can be imported from DMT and STL triangle files. Scanning acquisition performance is improved and points can be saved from a point-cloud scan each time there is a pause during the scan. Several point-cloud items can also now be created in a single point-cloud session without having to leave the full-screen acquisition view.

CNC surface inspection has been improved, making it easier to produce consistent results across a batch of components. New surface inspection groups provide better user control of point naming, and the positioning, contents and formatting of report images. It is also possible to reference CNC surface inspection groups directly in RPS alignments.

Finally, there are significant usability improvements for the CAD File Manager. It is now possible to import one or more CAD files by dragging and dropping them into the main graphics window. The highlighting and visualization of individual objects in CAD models is further improved, making it easier to identify named objects and levels.

About Delcam

Delcam is one of the world’s leading suppliers of CAM software and associated services, and also supplies systems for product design, tooling design, reverse engineering and inspection. The company has grown steadily since being founded formally in 1977, after initial development work at Cambridge University led by the late Donald Welbourn. It is now among the largest developers of product design and manufacturing software in the UK, with subsidiaries in America, Europe and Asia. Over 330 people are employed at Delcam’s Birmingham headquarters, with almost 400 staff working in the company’s overseas subsidiaries and around 200 more in its international joint ventures.

Delcam’s software and services help manufacturing companies to increase productivity, improve quality and reduce lead times. The company’s software is used in over 90 countries by more than 45,000 organizations. These customers range from multi-national corporations to independent designers, toolmakers and sub-contractors, and come from a wide variety of industries, including aerospace, automotive, electrical appliances, footwear, healthcare, motor sport, packaging, toys, sports equipment, jewelry and signmaking. On February 6, 2014, Delcam was acquired by Autodesk and now operates as a wholly-owned, independently-operated subsidiary.

Name:

Delcam PowerInspect 2016

Version:

(64bit) 2016 SP0 (build 16.1.0.01241027)

Home:

http://www.powerinspect.com

Interface:

multilanguage

OS:

Windows XP / Vista / 7even / 8 / 10

Size:

953.2 mb

发布日期: 2016-02-21