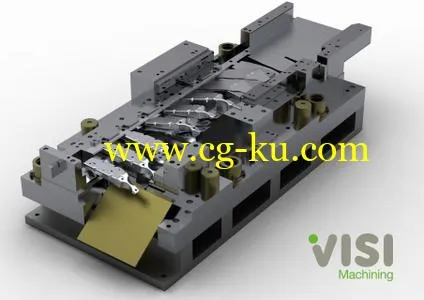

英国VISI-Series CAD/CAM 模具软件。

VISI-系列在全球模具业界被公认为是世界领先的CAD/CAM解决方案.它提供了一种独特而完整的应用组合,包括线架构、曲面及实体建模,全面的2D和3D加工策略,以及专业的塑模和级进模设计工具.这是2013年最新发行的版本。

VISI 是一套完整而全面的模具业专用的先进的 CAD/CAM/CAE 解决方案.

它提供了一套独特的整合工具, 完全集成了线架构, 曲面和实体混合建模, 综合高速路径专用的 2D, 3D 和 5 轴加工策略.

此外, VISI 还涉及到日益重要的模具设计领域, 拥有全 3D 的冲模设计 (Visi-Progress), 塑模设计 (Visi-Mould) 和塑胶模流分析 (Visi-Flow) 等模块.

针对不同软件供应商间的衔接, 实体至曲面, CAD/CAM 图形转换等要求, Vero Software 提供了专门的解决方案消除传统系统的转档问题.

VISI 提供了以下模组:VISI ModellingVISI Modelling 是所有 VISI 产品的基础, 提供一个基于行业标准 Parasolid 核心的健全的和强大的实体和曲面建模系统.

VISI Analysis在工程早期找出潜在的问题是非常有益的.

VISI Analysis 提供了一套专业的工具来对模型进行检查和准备.

VISI MouldVISI Mould 基于特殊的自动化行业之上, 提供了完整的塑模设计的解决方案, 引导客户完成整个的塑模开发流程.

VISI FlowVISI Flow 是一个独特的预测工具.

产品设计, 模具制作和模具设计者将受益于使用 Vero 的专业的射出模拟, 以实现成本效益和可靠的模具设计以及最佳的成型条件.

VISI ElectrodeVISI Electrode 是一种自动化模块, 用于加工和管理电极以及为精密制造而制作的电极治具, 并且努力加工塑胶模和冲压模上的特征.

VISI ProgressVISI Progress 是一种直观的工具, 用于制品分析, 3D 排料带, 以及级进模和冲压模的设计.

VISI Multi-SlidesVISI Multi-slides 是 VISI Progress 的延伸.

它被用于 “多滑块机床” 使用的凸轮设计, 及折弯工艺.

VISI Machining 2DVISI Machining 2D 是 VISI Progress 的延伸.

它被用于 “多滑块机床” 使用的凸轮设计, 及折弯工艺.

VISI Machining 3DVISI Machining 3D 在最复杂的 3D 制品上创建智能的刀具路径.

专注的高速铣削技术, 以平顺的运算法则建立高效率的 NC 代码.

VISI Machining 5 Axis5 轴加工拥有许多优势, VISI Machining 为操作者提供了卓有成效的解决方案, 建立有着先进的碰撞控制的高效的刀具路径.

VISI PEPS-Wire完全基于特征, VISI PEPS-Wire 采用了专为精密工程和模具工业研发的业界领先的 PEPS Wire 技术.

VISI BlankVISI Blank 是一款专为冲压模具行业解决复杂 3D 形状展开成 2D 形状的解决方案.

VISI ReverseVISI Reverse 是一款高层次专门为 3D 逆向工程, 3D 实体再现, 医学应用和多种其它学科所设计的软件解决方案.

官方最新消息:VISI-系列凭借其专业化的运用,给精密制造者们带来了超乎想象的生产力.

在处理不同软件间和传统系统所需的实体到曲面的转换方面,它提供了专业的解决方案.

英国华沃国际软件有限公司很高兴地宣布在VISI-系列的V15版本中发布VISI-5轴加工功能,这将为模具、航空航天和汽车工业提供完整的5轴解决方案由25种不同的加工方式组成了功能丰富的模块,允许用户自主选择需要的功能。

如果您正在加工叶片、深腔或发动机盖,VISI-5轴加工功能为您提供一套完整的解决方案。

Vero VISI 2018 R1 | 2.8 GbVero Software announces the availability of VISI 2018 R1.

The latest release provides a wide variety of new and enhanced items of functionality for both CAD and CAM, specifically for the mold and die market.

Innovative New Mold Design Tool Launched In VISI 2018 R1VISI 2018 R1 introduces a new Mold Tool module based on VISI’s Assembly-Ng technology.

This redeveloped module provides greater flexibility when constructing supplier and non-standard tool configurations.

Customisable templates, including the management of blank and predrilled plates, allow for easy tool layout creation and enhanced editing at any stage of the design process.

The ability to create project design and manufacturing technical reports have been included within the systems snapshot manager using data captured throughout the CAD and CAM project stages.

Further enhancements have been made within the plastic Flow warpage prediction module to improve result accuracy for complex technical polymers.

These improvements have been achieved by a complete revision of the algorithms for the Holding phase.

Pressure and flow rate calculation adjustments combined with the new shape solver, significantly improve the performance by reducing the calculation time up to 40 per cent.

Sheet metal developments in the progress strip development area and blank prediction include the ability to manage constraints of specific faces of a blanked component.

It is also possible to define the face constraint in X or Y, or in both directions, which is particularly useful for designers who want to blank only specific area’s of a model for step by step stage unfolding.

In addition, the process of managing strip layouts using double component geometry has been enhanced to reduce the development time of a 3D strip design.

CAM developments include faster geometry preparation, and an enhanced 2.

5-axis chamfering strategy which provides many quality updates including intelligent approach and retract points, advanced obstacle management, and significant speed improvements.

For 3D waterline milling, new adaptive stepdown capabilities can now manage variable Z steps for each independent area within the same piece being machined.

User interface improvements to the CAM navigator will see the build process status on the operation itself allowing the process manager to be switched off if required.

Tool sheet reports have been updated where the user can benefit from the enhancements to the snapshot manager.

In addition, or anyone requiring hole information generated from the feature recognition, there is also the added benefit of exporting the data to csv files for external use.

Finally, sharing process knowledge is key to tracking the digital thread throughout the entire manufacturing process.

A new VISI-to-PC-DMIS interface enables PC-DMIS to read the native VISI CAD file directly with annotation and points previously defined in VISI loaded automatically into PC-DMIS to be used for quality control purposes.

About Vero Software.

Vero Software is a world leader in CAD CAM software with a proven track record of reliable product delivery.

Vero develops and distributes software for aiding the design and manufacturing processes, providing solutions for the tooling, production engineering, sheet metal, metal fabrication, stone and woodworking industries.

The company's world-renowned brands include Alphacam, Cabinet Vision, Edgecam, Machining STRATEGIST, PEPS, Radan, SMIRT, SURFCAM, VISI, and WorkNC, along with the production control MRP system Javelin.

Despite the diversity of application, these solutions have one thing in common: they all address the rising challenges of achieving manufacturing efficiencies and bring huge value to the operations where they are deployed.

Product:Vero VISIVersion:2018 R1Supported Architectures:x64Language:englishSystem Requirements:PCSupported Operating Systems:Windows 7even or newerSize:2.8 Gb

发布日期: 2018-01-05