英国VISI-Series CAD/CAM 模具软件。

VISI-系列在全球模具业界被公认为是世界领先的CAD/CAM解决方案.它提供了一种独特而完整的应用组合,包括线架构、曲面及实体建模,全面的2D和3D加工策略,以及专业的塑模和级进模设计工具.这是2013年最新发行的版本。

VISI 是一套完整而全面的模具业专用的先进的 CAD/CAM/CAE 解决方案.

它提供了一套独特的整合工具, 完全集成了线架构, 曲面和实体混合建模, 综合高速路径专用的 2D, 3D 和 5 轴加工策略.

此外, VISI 还涉及到日益重要的模具设计领域, 拥有全 3D 的冲模设计 (Visi-Progress), 塑模设计 (Visi-Mould) 和塑胶模流分析 (Visi-Flow) 等模块.

针对不同软件供应商间的衔接, 实体至曲面, CAD/CAM 图形转换等要求, Vero Software 提供了专门的解决方案消除传统系统的转档问题.

VISI 提供了以下模组:VISI ModellingVISI Modelling 是所有 VISI 产品的基础, 提供一个基于行业标准 Parasolid 核心的健全的和强大的实体和曲面建模系统.

VISI Analysis在工程早期找出潜在的问题是非常有益的.

VISI Analysis 提供了一套专业的工具来对模型进行检查和准备.

VISI MouldVISI Mould 基于特殊的自动化行业之上, 提供了完整的塑模设计的解决方案, 引导客户完成整个的塑模开发流程.

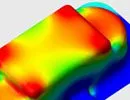

VISI FlowVISI Flow 是一个独特的预测工具.

产品设计, 模具制作和模具设计者将受益于使用 Vero 的专业的射出模拟, 以实现成本效益和可靠的模具设计以及最佳的成型条件.

VISI ElectrodeVISI Electrode 是一种自动化模块, 用于加工和管理电极以及为精密制造而制作的电极治具, 并且努力加工塑胶模和冲压模上的特征.

VISI ProgressVISI Progress 是一种直观的工具, 用于制品分析, 3D 排料带, 以及级进模和冲压模的设计.

VISI Multi-SlidesVISI Multi-slides 是 VISI Progress 的延伸.

它被用于 “多滑块机床” 使用的凸轮设计, 及折弯工艺.

VISI Machining 2DVISI Machining 2D 是 VISI Progress 的延伸.

它被用于 “多滑块机床” 使用的凸轮设计, 及折弯工艺.

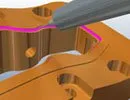

VISI Machining 3DVISI Machining 3D 在最复杂的 3D 制品上创建智能的刀具路径.

专注的高速铣削技术, 以平顺的运算法则建立高效率的 NC 代码.

VISI Machining 5 Axis5 轴加工拥有许多优势, VISI Machining 为操作者提供了卓有成效的解决方案, 建立有着先进的碰撞控制的高效的刀具路径.

VISI PEPS-Wire完全基于特征, VISI PEPS-Wire 采用了专为精密工程和模具工业研发的业界领先的 PEPS Wire 技术.

VISI BlankVISI Blank 是一款专为冲压模具行业解决复杂 3D 形状展开成 2D 形状的解决方案.

VISI ReverseVISI Reverse 是一款高层次专门为 3D 逆向工程, 3D 实体再现, 医学应用和多种其它学科所设计的软件解决方案.

官方最新消息:VISI-系列凭借其专业化的运用,给精密制造者们带来了超乎想象的生产力.

在处理不同软件间和传统系统所需的实体到曲面的转换方面,它提供了专业的解决方案.

英国华沃国际软件有限公司很高兴地宣布在VISI-系列的V15版本中发布VISI-5轴加工功能,这将为模具、航空航天和汽车工业提供完整的5轴解决方案由25种不同的加工方式组成了功能丰富的模块,允许用户自主选择需要的功能。

如果您正在加工叶片、深腔或发动机盖,VISI-5轴加工功能为您提供一套完整的解决方案。

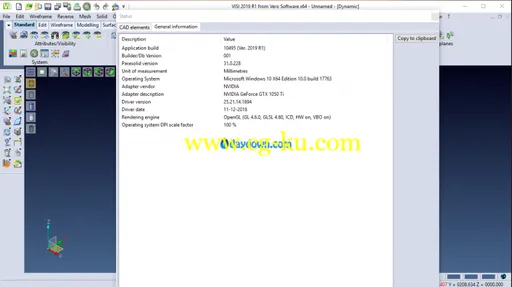

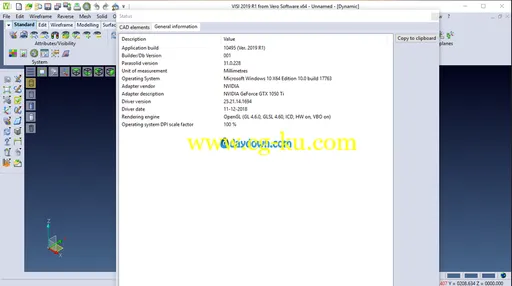

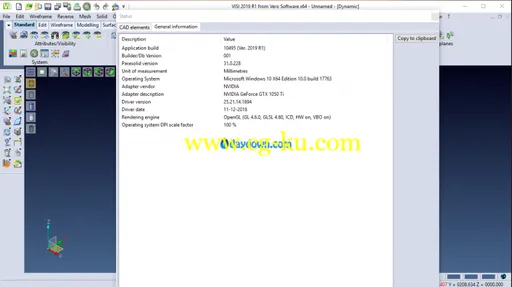

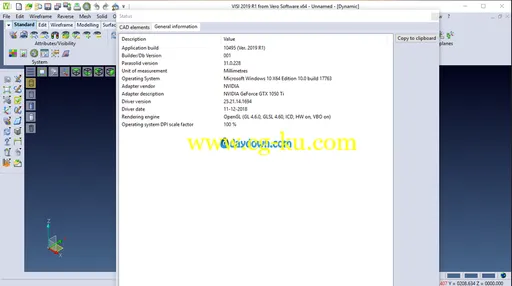

x64 | Language:Multilanguage | File Size: 2.76 GBDescription:The 2019 R1 release of VISI software includes a boost for reverse engineering, along with a range of new and enhanced CAD/CAM functions for the mold and die market.

Reverse Engineering Features And Enhancements:As part of a larger synergy project for reverse engineering and casting, VISI 2019 R1 introduces an extended direct interface to multiple portable measuring arms and Leica scanning devices from Hexagon.

Together with the enhanced dedicated module, it provides a reverse engineering solution, as well as the ability to generate casting and stock models from VISI’s existing modelling and machining environment.

It means that a points cloud can be loaded either directly or indirectly, and the relative mesh can be created by setting different options for refining and smoothing.

Surfaces can be created automatically or semi-automatically by extracting different key geometrical references from the refined mesh.

And scan data, stock or reference casting mesh models can easily be aligned to the original geometrical CAD model using dedicated commands to allow comparisons, gap analysis and optimised toolpath processes.

Ejector Pin Labelling For Plastic Mold Design:The new ejector pin labelling functionality, which has been specifically produced for plastic mold designers, enables all the ejector pins in a mold design project to be identified in a table by a user-defined label.

This feature simplifies the maintenance process of the mold itself where one or more ejector pins need to be replaced.

It easily identifies any ejector pin for maintenance purposes, and updates it if it needs replacing.

Conformal Cooling Channels For Plastic Mold Design:VISI 2019 R1 introduces a function for advanced sketching of conformal cooling channels.

It allows the use of wireframe circuits, previously created in CAD, along with selecting predefined or user sections, and automatically creates the conformal channels to form the desired cooling circuit.

It’s also possible to edit those channels, even after subtraction from the mold insert.

All the information defined on the conformal cooling during the design phase are automatically managed by VISI Flow’s thermal analysis.

The Flow thermal analysis itself has also been enhanced to provide a graphical temperature display on a dynamic section on the inserts.

The result is a simplified process and time saving of the mold design and Flow analysis.

Pressure Pad Management For Progressive Die Design:The blanking process has been enhanced, to set the faces on the model affected by the pressure pad, by simply defining the relative force to apply.

This allows the material to flow, based on the applied force on the pressure pad.

Users can also set constraints to simulate the effect of a uniformly distributed blank holder force.

It’s possible to define a friction value and the force value to be applied for the blanking phase.

This leads to a more accurate blanking process, which gives additional support to the user during the design phase of the die.

System Requirements:-OS:Windows 7, Windows 8.1 and Windows 10, 64 bit version (only Professional version supported)-GPU:Graphic board supporting either OpenGL or DirectX with a minimum 1280x1024 resolution, supporting at least 65.000 colors-Memory:4 Gbyte RAMPower users are recommended to use:-OS:Windows 7, Windows 8.1 and Windows 10, 64 bit version (only Professional version supported)-GPU:Graphic board supporting either OpenGL or DirectX with a minimum 1920X1080 resolution, supporting at least 65.000 colors-Memory:16 Gbyte of RAM-Disk Space:SSD HardDisk

发布日期: 2018-12-14