PowerSHAPE 是一款功能强大,应用广泛的CAD造型软件,使您能快速、轻松地完成复杂形状零件的造型。基于世界领先的实体造型核 Parasolid,配之PowerSHAPE独特的曲面和三角网格建模工具,PowerSHAPE 可建构出任何形状的形体。

主产品 (可独立使用)

• PowerSHAPE用于设计和制造的线框、曲面、实体和装配造型

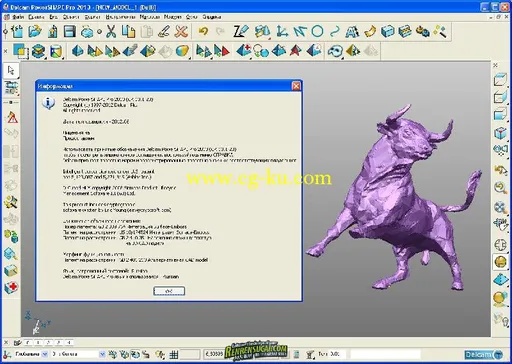

• PowerSHAPE Pro 增加了三角形造型,再造工程及一些高级设计工具

• Delcam Toolmaker增加了3D模具设计向导和标准模具零件库

配套产品 (需和其它 Delcam 软件配合使用)

• Delcam Designer ArtCAM 平台下进行线框、曲面、实体和装配造型

• PowerMILL Modelling PowerMILL 平台下进行线框和曲面造型

• PowerSHAPE CompanionPartMaker和FeatureCAM平台下进行线框、曲线实体和装配造型

• Delcam Electrode EDM 电极设计 (可独立使用或在 PowerMILL 平台下使用)

PowerSHAPE易学易用,它整合线框、曲面、实体和装配造型为一体。其主要优势如下:

• 智能曲面产生,轻松设计出复杂的3D形状

• 智能光标,快速、精确地建构几何形体

• 基于Parasolid,快速、可靠、方便的数据交换

• Solid Doctor 实体诊断器,帮助查找和修复输入数据中的缺陷

• 整合的绘图工具,产生完整、详细的2D工程绘图

PowerSHAPE Pro 是一完整的造型和再造工程解决方案,强大的三合一造型工具集曲面、实体和三角形造型为一体,易学易用。PowerSHAPE Pro 可通过扫描数据再造曲面和实体模型,精确、完整地还原原始设计创意。

使用 PowerSHAPE Pro 可:

• 直接将三角形包裹到实体和曲面,在零件上产生高品质的装饰组件

• 交互雕刻和光顺三角形,整理扫描数据,增加或删除特征

• 使用强大的摹仿变形工具来快速、简便地修改零件

• 复杂造型过程中将三角形视为实体来操作

• 通过网格或扫描数据快速、精确产生紧缩包裹曲面

• 提供快速分模,将模型分为型芯和型腔

• 产生基于特征的实体模型,快速产生多个变体

• 使用易于理解的分析图检测曲面和扫描数据的拟合精度

PowerMILL Modelling 和配套产品

提供制造过程中车间所需的全部造型工具。

PowerMILL Modelling 和其配套产品的使您能:

• 快速修复质量不好的输入数据

• 封顶孔,简化加工

• 合并面片,改善精加工表面质量

• 为多轴加工产生参考曲面

Delcam PowerSHAPE-e是一款世界级的最佳免费CAD设计软件,这款由Delcam公司推出的完全免费特别版PowerSHAPE包含了线框、曲面、实体和三角形面片结合一体的造型设计工具,其完全造型功能是Delcam的专利技术。

产品特点

用户可免费进行无数多个的新的概念设计,可无次数限制地保存模型,它也是您学习和掌握先进的CAD造型技术、进行制造成本估算的极佳免费工具。

使用Delcam PowerSHAPE-e的用户可免费进行无数多个的新的概念设计,仅当最终模型设计需要输出投入生产时才需付费。

PowerSHAPE-e是全球首例按次付费的软件,全部PowerSHAPE-e都以加密格式保存,用户仅需付200英镑就可将一个模型设计数据转换到其它软件。当然,用户可任意传看、产生和修改模型,直到模型提交加工才需付费。

Delcam PowerSHAPE 2013 SP0 with PS-Catalogues 2013 SP0

The 2013 release of Delcam’s PowerSHAPE CAD system includes enhancements to its direct modelling and reverse engineering capabilities that will make the software both more flexible and even easier to use. In addition, the solid and surface modelling options have been made faster and even more robust.

PowerSHAPE provides the most comprehensive range of modelling techniques available in a single CAD program. Having all the different technologies in the same package reduces the need to transfer data between multiple programs and so streamlines the whole product development process. The broad range of functionality makes PowerSHAPE ideal for the re-engineering of existing products into improved designs or for creating specialised items. At the same time, the combination of quick and easy direct modelling options, together with powerful and flexible surface modelling, makes PowerSHAPE the perfect choice for design for manufacture, especially when converting product designs into tooling designs.

The most important new option in PowerSHAPE’s direct modelling functionality is “Replace Face”. This allows a selected face or group of faces to be replaced with another face or group of faces, either from the same solid or from a separate solid or surface model.

In its most basic form, “Replace Face” can be used for offsetting surfaces of the model to provide machining allowances or clearances for electrodes for EDM. It can also be used for more complex modifications to product designs. In all cases, any other faces within the design that are affected by the change are extended and re-trimmed as necessary to maintain a closed solid.

A second new option that will be of particular interest to tooling designers will be the “Solid Core” command. This selects automatically the smallest rectangular or cylindrical shape that will fully cg-ku.com enclose a group of solid faces. It can be used to create blanks for the manufacture of electrodes or when modelling slides within moulds to accommodate undercuts. The shapes can be selected from spreadsheets, for example one showing different standard sizes for electrode blanks, that can be edited to each company’s specifications.

The main improvement to the existing direct modelling tools has been a simplification of the selection and editing of faces. Groups of faces can now be selected by surrounding them with a boundary, either by dragging the mouse or by clicking a series of points. Simpler methods have been added to then rotate the selected faces around a point or a cylinder, or to move them along a line.

For reverse engineering, PowerSHAPE now allows point-cloud data to be captured directly. Point data can be displayed on-screen instantly as a laser attachment is passed over the object being scanned. This ensures that all the required information can be captured as any gaps in the data will be apparent immediately.

Another new option in PowerSHAPE 2013 is the ability to perform 2D nesting of 2D profiles or 3D parts. Once the numbers of each component required and the minimum spacing needed between each item has been specified, PowerSHAPE calculates the most efficient layout using the minimum amount of material. The shape of any unused material can be saved so that it can be used for later projects. The nesting option will be important for any company using sheet materials, including those in the press tool, composites and footwear industries, or for laying out multiple 3D parts for effective machining.

About Delcam plc

Delcam is a world-leading developer and supplier of advanced CADCAM software, with more than 35,000 customers in over 80 countries. These clients vary from global names like Nike, Boeing and Mattel to small start-ups and individual craftsmen. Founded 30 years ago, we are the largest developer of product development software in the UK, with subsidiaries in Europe, America and Asia. Our global success has been recognised with many awards, including three Queen’s Awards for Enterprise

☉网站资源均由会员发布,资源均来自网络。

☉网站及会员对该资源不拥有所有权,所有权归版权方所有。

☉资源未经过安装测试与安全检测,使用者后果自负与本网站无关。

☉资源仅供学习研究之用,请24小时内删除,不得用于商业,如用于商业用途,请购买正版。

☉如无意中侵犯了您的权益,请及时联系我们。我们将及时删除相关链接并进行整改。

发布日期: 2012-7-11