重新定义CAD/CAM/CAE效率和产品开发决策

西门子为其CAD/CAM/CAE集成解决方案全方位地增加重要功能,并宣布支持新的精确定义产品生命周期管理技术框架

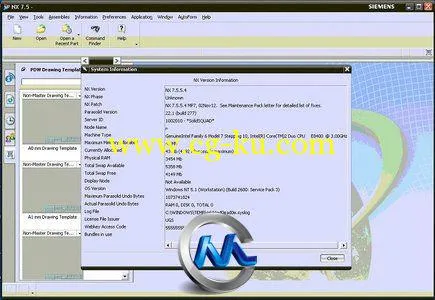

中国上海,2010年5月20日- 西门子工业自动化业务部旗下机构、全球领先的产品生命周期管理(PLM)软件与服务提供商Siemens PLM Software今天宣布为其NX™ 软件增添了最新增强功能。NXTM软件是一款集计算机辅助设计、制造和工程分析(CAD/CAM/CAE)于一体的集成解决方案。

于2010年上海世界博览会上推出的最新NX7增强版全方位地增加了重要的新功能。在今天发布的另一份新闻中,Siemens PLM Software发布了全新的精确定义产品生命周期管理(HD-PLM)技术框架,NX 与Teamcenter® 软件数字化生命周期管理系统是首款支持这一技术框架的软件产品。

Siemens PLM Software产品设计解决方案部副总裁Joan Hirsch表示:“我们新发布的HD-PLM技术框架在NX软件中提供了一个可视的直观环境,有助加快产品研发的决策过程,为我们的客户和整个行业创造重要价值。不仅如此,NX7增强版的价值不仅限于由许多新增功能所带来的优势,还在于该软件产品在设计、分析和零部件制造模块等几方面的功能都得到了增强。这些优势能使终端用户的生产效率提高至80%。”

精确定义产品开发决策

随着去年三维精确描述(HD3D)环境的发布和这一技术在新版NX中的增强,Siemens PLM Software开始实施将HD-PLM技术全面融入其企业级解决方案的计划。HD3D在HD-PLM技术框架之下将NX和Teamcenter的强大功能结合起来,以可视的直观方式为全球分布的产品研发部门提供了解、协同和决策所必需的信息。

HD3D通过产品研发决策支持和分析解决方案,实现了HD-PLM的四项目标。该解决方案通过对用户进行个性化设置将用户置于适当环境下,主动协助用户完成任务,帮助做出协同决策,通过直接的信息展示使用户拥有清晰的体验,并参照已有基本原理验证用户决策的正确性。HD3D使用户能够通过交互式导航直观地理解PLM数据,并深入获取所需的详细信息。通过产品的3D展示,用户能轻易地进入正确的环境,从而快速地回答有关项目状态、设计变更、团队责任、各种事项、问题、费用、供应商等方面的问题。颜色编码、屏幕上的标记和图例,有助快速做出直观评价,并对产品开发问题和决策标准做出解释。

HD3D还与NX验证检测工具一起构成一个直观的互动平台,从而加快根据要求验证产品设计的速度。丰富的可视反馈信息使用户能够在整个研发过程中监控关键性功能要求,支持用户充满信心地快速决策,并充分确保产品质量。

DEVELOP3D杂志创始人兼主编AI Dean说:“Siemens PLM Software此次发布的新版本是一次很大的提升,通过在其丰富的产品范围内整合HD3D延伸了HD-PLM的概念。利用NX和Teamcenter将隐藏在数据库中的数据按照图形和内在关联性显示出来,用户能够快速评估各种产品研发问题和潜在瓶颈。反之,这套系统也能帮助流程中的每一位参与者更加自信和高效地做出明智决定,从而帮助客户大幅度地提高生产效率”。

重新定义产品设计效率

除了支持HD-PLM,NX7还具有许多新的功能,可重新定义产品开发的效率。在紧密集成的CAD应用程序内,NX7的新增功能包括了多种快速设计工具 , 如更合理的草图工具、运用扩展的同步建模技术进行自由形状曲面的模型转换,可显著改进二维设计和绘图的DraftingPlus工具等。

新型快速设计工具可加快二维草图的绘制和定位,自动推断约束条件和建模意图。因此,建模所需的时间可缩短最高达50%。

将具有开创性的同步建模技术与NX自由曲面建模集成,可以应用于任何几何体,包括倒入的复杂形状设计的模型,大大改变了模型创建和修改的过程。用户可从简单的几何构型设计开始,运用先进的建模工具,在更少的时间内完成复杂的模型建立。

同步建模技术进一步扩展增强了特征阵列、装配、 薄壁几何体、倒圆、倒角等功能,而且方法得到改进,有助几何体模型的重复使用。

NX DraftingPlus是一套新型设计工具,它进一步增强了NX的二维功能和与三维模型的集成。其基于角色的界面将用户置于适当的二维设计工作环境中;它具有强大的性能,如功能强大的、能够从二维曲线生成三维几何体的曲线绘制和修改工具,并且减少了工艺步骤,简化了产品设计流程。NX DraftingPlus实现了单一设计环境下的二维、三维设计工作流程整合,从此不再需要使用任何单独的二维CAD软件。

重新定义产品分析和仿真的效率

实践证明,NX设计和分析环境可大大缩短工程师在设计过程中验证产品性能的时间。最新发布的NX提供了有史以来对CAE功能最多的提升。这些提升重新定义了CAE的效率,进一步改善了与产品设计的集成,在多学科仿真解决方案中扩展NX CAE的领导地位,并且使数字仿真模型与测得的数据相关联。因此,工程师们可在较短的时间内做出更合理的决策,生产出更优质的产品。

NX7中加入了新的模型准备流程,这个流程可帮助用户处理复杂的几何体,如对薄壁部件划分网格,增强梁和螺栓建模等等,使集成设计和CAE效率得以进一步增强。许多新增功能简化了设计分析之间的数据交互,增强了耦合分析的能力。NX通过直观的有限元建模方式,简化了分析师处理大型复杂模型的方式,并使工程师们使用的系统模型能够随着设计逼真度的提高而得到更新。

NX CAE与各种广泛使用的解算技术的结合扩大了其优异的集成性。它增添了新的多物理集成解决方案,包括柔性体的耐久性和弹性分析,以及更多可用于结构、热量和流量分析的解决方案。分析机械装置部件的柔性很重要,因为它会影响几何体,导致严重的设计问题。有了NX 7,工程师就能够使用高逼真模型验证设计,因为高逼真模型将柔性分析和刚体运动结合起来,以评价组件柔性体对机械装置性能和耐久力的影响。

NX 7引入了两种新的CAE产品,即NX 有限元(FE)模型关联和NX 有限元模型更新。这两种新产品都是分析型系统,其直观的用户界面根据CAE分析师的需要设计而成。它们构成一个完整的综合系统,可用于模态分析、预备测试计划、测试分析关联和模型更新。

荷兰达门船舶有限公司研发部项目工程师Jerry Baffa表示,“当分析结果要求对设计进行变更时,我们就可以应用高效的同步建模技术。网格重划轻而易举,设计周期大大缩短。”

重新定义零部件制造效率

NX将CAM和CMM功能集成在一起,这是世界零部件制造最尖端的软件解决方案。NX 7进一步重新定义了零部件制造的效率。它引入了两种新的应用程序,将用户置于具体的编程任务环境中,大大缩短了叶轮类复杂形状零件的编程时间,同时实现三座标测量机(CMM)数控测量编程效率最大化。

NX 叶轮加工使复杂的5轴、多叶片旋转部件的数控编程速度大大加快。这种为集合了叶盘结构和叶轮而设计的NX CAM集成应用程序,提供了一套针对具体环境的自动化功能,可大大简化创建智能工具路径的任务,而这些路径是制造复杂部件所必须的。这一新功能得到了NX CAM中多项已有功能的支持,其中包括直接由后处理器输出驱动的仿真加工,有助于对数控编程结果进行验证。NX 叶轮加工解决方案能够生产出高质量的产品,而所需时间仅相当于普通轧制软件的一半。

NX CMM数控测量编程在包括坐标测量机和部件在内的3维实体模型环境下工作。由于实现了自动化,直接从3D设计模型所附的PMI(产品制造信息)数据直接自动生成检验结果和探查路径,使潜在编程检测时间最高可缩短80%。 这一集成化的应用程序添加了模拟和防止碰撞功能,可用于验证CMM编程决策,加工和探测数据库内容,从而大幅提高CMM编程效率。

Bringing High Definition PLM to product development, Siemens PLM NX redefines productivity with a powerful suite of integrated CAD, CAE and CAM solutions. Siemens PLM NX takes full advantage of the High Definition PLM Technology Framework to improve decision making throughout the product development process.

NX is a next-generation digital product development system that helps companies transform the product lifecycle. With the industry's broadest suite of integrated, fully associative CAD/CAM/CAE applications, NX touches the full range of development processes in product design, manufacturing and simulation.

The problem where the environment variable UG_initialJournalDir_WIN was not working correctly is fixed.

The problem in Drafting where the dimensions on I-deas drawings were migrated to NX with missing or incomplete tolerance values is fixed.

The problem in Translators where an assembly exported to a STEP file resulted in wrong component positions when re-imported is fixed.

The problem in Modeling where editing an instance array of threaded holes caused the alert "Unable to modify tool due to missing target face" is fixed.

The problem in Teamcenter Integration for NX where the File > Save As dialog did not correctly increment the assigned Item ID is fixed.

The problem in Modeling where some WAVE linked features remained marked in the Part Navigator as 'Newly Broken' after Feature Playback is fixed.

The problem in Manufacturing where the operation variable 'mom_channel_id' was overridden is fixed. A new variable 'mom_oper_channel_id' will be installed for the channel ID of an operation. This variable will be reset for each operation.

The problem in Teamcenter Integration for NX where the 'Overwrite Existing' option for File > Export > PDF did not overwrite is fixed.

The problem in Translators where certain DWG files could not be imported is fixed.

The problem in NX Open where the GRIP statements BLANK and UNBLANK sometimes failed when the specified objects were group members is fixed.

The problem in Manufacturing where Feature Identification returned a reduced set of DRILL_SIZE_HOLE attributes is fixed.

The problem in Teamcenter Integration for NX where the reference "APPUID-OBJ" was missing when an altrep was created in Teamcenter is fixed.

The problem in Manufacturing where tool path generation was slow if the operation had part geometry defined in the geometry group is improved.

The problem in Routing where a Pin Listing Annotation did not include references to Device Replacement Ports is fixed.

The problem in Assemblies where the Replace Component operation failed to maintain constraint associativity when a component part that served as the base part for a constrained promotion was replaced with a cloned version of that same component part is fixed.

The problem in Manufacturing where the Parallel Generate process did not terminate is fixed.

The problem in Manufacturing where a legacy Turning spun outline generated using the fall-back method failed to update is fixed.

The problem in Teamcenter Integration for NX where it sometimes was not possible to import files into Teamcenter after modifying the file in Native is fixed.

The problem in Teamcenter Integration for NX where some assemblies were always marked as modified when opened is fixed.

The problem in Teamcenter Integration for NX where the performance was slow when expanding the Reuse Routing Part Library node is improved.

The problem in Teamcenter Integration for NX where sometimes a part failed to open and caused the error "Internal Hookup error - invalid tag" is fixed.

The problem in Modeling where expression edits in some large assemblies caused degraded update performance is improved.

The problem where File > Export > PDF sometimes resulted in an empty or invalid file is fixed.

The problem in Manufacturing where instanced Surface Contouring operations could not be generated as a group is fixed.

The problem where saving a part containing a deformable feature caused a, "MOM_TCL: Interpreter returned error when doing event” is fixed.

The problem in Teamcenter Integration for NX where start up performance was degraded with Teamcenter 9.1 is improved.

The problem in NX Open where the routine 'UF_MODL_copy_paste_features' failed for some User Defined Features is fixed.

The problem in Manufacturing where an NX Open API program failed to create feature groups is fixed.

About Siemens AG

Siemens AG is a German engineering conglomerate, the largest of its kind in Europe. Siemens has international headquarters located in Berlin, Munich and Erlangen. The company has three main business sectors: Industry, Energy, and Healthcare; with a total of 15 divisions. Worldwide, Siemens and its subsidiaries employ approximately 420,800 people in nearly 190 countries and reported global revenue of 76.651 billion euros for the year of 2009. Siemens AG is listed on the Frankfurt Stock Exchange, and has been listed on the New York Stock Exchange since March 12, 2001.

发布日期: 2012-11-20