DEFORM系列软件介绍

1. DEFORM-2D(二维)

适用于各种常见的UNIX工作站平台(HP,SGI,SUN,DEC,IBM)和Windows-NT微机平台。可以分析平面应变和轴对称等二维模型。它包含了最新的有限元分析技术,既适用于生产设计,又方便科学研究。

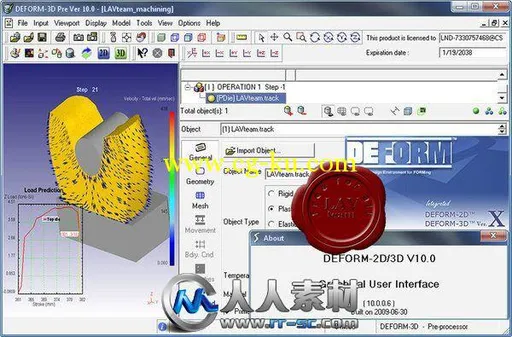

2. DEFORM-3D(三维)

适用于各种常见的UNIX工作站平台(HP,SGI,SUN,DEC,IBM)和Windows-NT微机平台。可以分析复杂的三维材料流动模型。用它来分析那些不能简化为二维模型的问题尤为理想。

3. DEFORM-PC(微机版)

适用于运行Windows 95,98和NT的微机平台。可以分析平面应变问题和轴对称问题。适用于有限元技术刚起步的中小企业。

4. DEFORM-PC Pro(Pro版)

适用于运行Windows 95,98和NT的微机平台。比DEFORM-PC功能强大,它包含了DEFORM-2D的绝大部分功能。

5. DEFORM-HT(热处理)

附加在DEFORM-2D和DEFORM-3D之上。除了成形分析之外,DEFORM-HT还能分析热处理过程,包括:硬度、晶相组织分布、扭曲、残余应力、含碳量等。

DEFORM功能

1. 成形分析

冷、温、热锻的成形和热传导耦合分析(DEFORM所有产品)。

丰富的材料数据库,包括各种钢、铝合金、钛合金和超合金(DEFORM所有产品)。

用户自定义材料数据库允许用户自行输入材料数据库中没有的材料(DEFORM所有产品)。

提供材料流动、模具充填、成形载荷、模具应力、纤维流向、缺陷形成和韧性破裂等信息(DEFORM所有产品)。

刚性、弹性和热粘塑性材料模型,特别适用于大变形成形分析(DEFORM所有产品)。

弹塑性材料模型适用于分析残余应力和回弹问题(DEFORM-Pro, 2D, 3D)。

烧结体材料模型适用于分析粉末冶金成形(DEFORM-Pro, 2D, 3D)。

完整的成形设备模型可以分析液压成形、锤上成形、螺旋压力成形和机械压力成形(DEFORM所有产品)。

用户自定义子函数允许用户定义自己的材料模型、压力模型、破裂准则和其他函数(DEFORM-2D,3D)。

网格划线(DEFORM-2D,PC,Pro)和质点跟踪(DEFORM所有产品)可以分析材料内部的流动信息及各种场量分布

温度、应变、应力、损伤及其他场变量等值线的绘制使后处理简单明了(DEFORM所有产品)。

自我接触条件及完美的网格再划分使得在成形过程中即便形成了缺陷,模拟也可以进行到底(DEFORM-2D,Pro)

多变形体模型允许分析多个成形工件或耦合分析模具应力(DEFORM-2D,Pro,3D)。

基于损伤因子的裂纹萌生及扩展模型可以分析剪切、冲裁和机加工过程(DEFORM-2D)。

2. 热处理

模拟正火、退火、淬火、回火、渗碳等工艺过程

预测硬度、晶粒组织成分、扭曲和含碳量。

专门的材料模型用于蠕变、相变、硬度和扩散。

可以输入顶端淬火数据来预测最终产品的硬度分布。

可以分析各种材料晶相,每种晶相都有自己的弹性、塑性、热和硬度属性。

混合材料的特性取决于热处理模拟中每步各种金属相的百分比。

DEFORM用来分析变形、传热、热处理、相变和扩散之间复杂的相互作用。如图所示,各种现象之间相互耦合。拥有相应的模块以后,这些耦合效应将包括:由于塑性变形功引起的升温、加热软化、相变控制温度、相变内能、相变塑性、相变应变、应力对相变的影响以及含碳量对各种材料属性产生的影响等。

This summer Scientific Forming Technologies Corp. is introducing new versions of its DEFORM software, which is used by product designers to analyze metal forming, heat treatment, machining and mechanical joining.

Among the system improvements in DEFORM v10.2, Scientific Forming lists an upgrade to the datasharing protocol (MPICH2) for better 64-bit performance in PCs with multi-core processing. There is also support for the 64-bit user subroutine in Windows and Linux systems, and improved batch queue stability in Linux.

In terms of simulation capabilities, the new DEFORM release offers shape morphing and parametric design features in its 3D geometry tool, and its 2D-to-3D translation method will handle multi-phase transformation data. The program has a new Patran data file format importer capability, too.

Optional in 10.2 release users will find dual-frequency induction heating capability, enhanced 3D extrusion simulation, and a mesoscale microstructure/ material model. In addition, there is an integrated 2D-3D machining distortion model, and the 2D torsion mode now supports elastic-plastic materials.

As these updates, and others, make clear, simulation software is growing more sophisticated in its functionality thanks to the accumulated experience of real-time users as well as the progress of computer science: the advent of multicore processing is just one example of a development with significant practical advantages to users. But, the frequency of product updates is what makes forging processing more sophisticated in real time.

About Scientific Forming Technologies Corporation

Scientific Forming Technologies Corporation (SFTC) was incorporated in Ohio in August 1991 by former Battelle employees to provide state of the art process design and analysis technologies to the materials forming industries. SFTC acquired from Battelle the DEFORM business in October 1991, and is currently supporting hundreds of user sites worldwide. DEFORM is the one of the most widely used FEM (Finite Element Method) software for metal forming and die analysis by the industry.

DEFORM serves the aerospace, automotive, off road, general transportation, fastener, oil field, ordnance and many other industries with state of the art simulation capabilities in deformation and die stress analysis. It has been used to solve metal forming problems, optimize processes, and analyze loads and stresses on forming dies for thousands of industrial cases throughout the 1990?s. DEFORM was first released in its 2D workstation version in 1989. In 1993, DEFORM-3D was released to analyze full three dimensional problems on engineering workstations. DEFORM-PC was released in 1994, making this powerful technology available to small to medium sized forming plants.

发布日期: 2013-2-17